Transfer Express Heat Press: The Ultimate Guide To Revolutionize Your Printing Business

Transfer express heat press technology has become a game-changer in the printing industry. If you're looking to enhance your production capabilities, this guide will walk you through everything you need to know about transfer express heat presses. From understanding the basics to exploring advanced techniques, this article is designed to help you make informed decisions for your business.

As the demand for personalized products continues to grow, businesses are turning to transfer express heat presses to meet customer expectations. This innovative technology allows for high-quality prints on various materials, making it an essential tool for entrepreneurs and professionals alike.

In this comprehensive guide, we will explore the benefits, applications, and best practices of using transfer express heat presses. Whether you're a beginner or an experienced user, this article will provide valuable insights to help you maximize the potential of your equipment.

- How To Reach Live Ebay Customer Service Phone Number A Comprehensive Guide

- Danny Masterson Movies And Tv Shows A Comprehensive Guide

Table of Contents

- Introduction to Transfer Express Heat Press

- History and Evolution of Heat Press Technology

- Types of Transfer Express Heat Press Machines

- Applications of Transfer Express Heat Press

- Benefits of Using Transfer Express Heat Press

- Tips for Maximizing Efficiency

- Maintenance and Troubleshooting

- Comparison with Other Printing Methods

- Market Trends and Future Prospects

- Conclusion

Introduction to Transfer Express Heat Press

Transfer express heat press technology involves applying heat and pressure to transfer designs onto various materials. This method is widely used in the apparel industry for printing custom t-shirts, hoodies, and other garments. The process is straightforward: a design is printed on special transfer paper, which is then transferred onto the material using a heat press machine.

One of the key advantages of transfer express heat press is its versatility. It can be used on a wide range of materials, including fabrics, ceramics, and even metal. This makes it an ideal choice for businesses looking to diversify their product offerings.

How Does Transfer Express Heat Press Work?

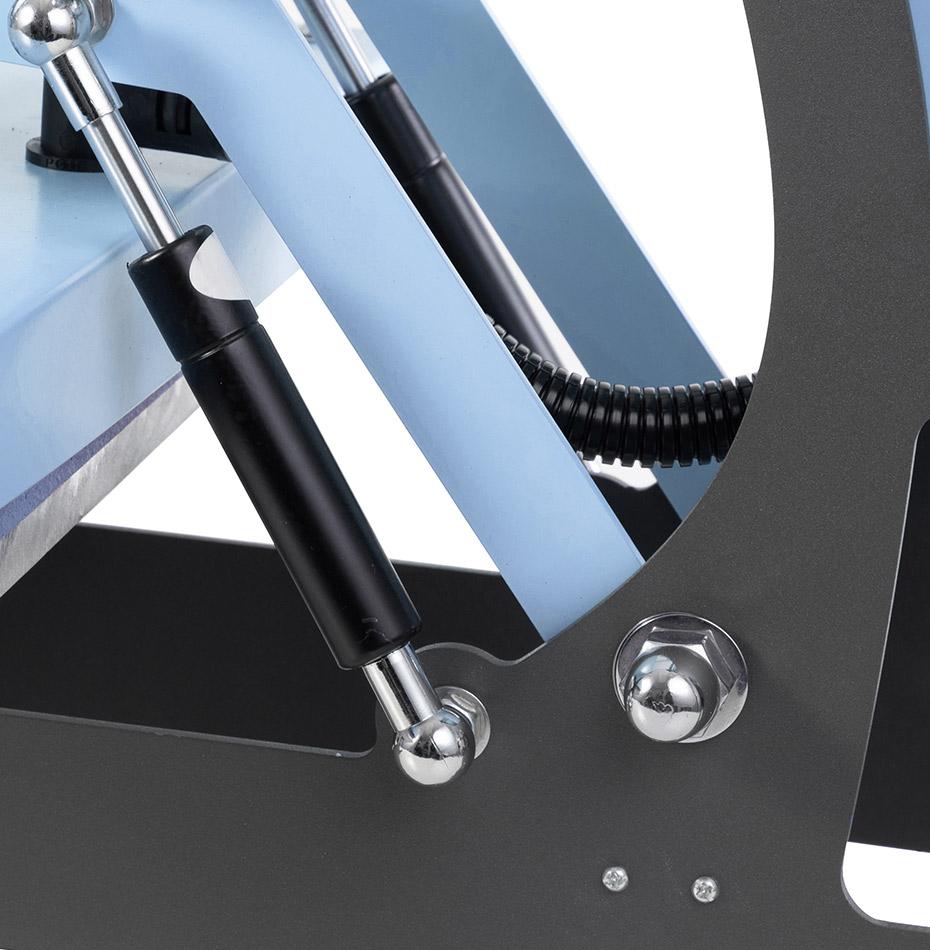

The transfer express heat press operates by applying heat and pressure to the material. The machine is equipped with a heating element and a pressure plate, which work together to transfer the design from the transfer paper to the material. The temperature and pressure settings can be adjusted to suit different materials and designs.

- Monroe County Fire Wire Your Comprehensive Guide To Safety And Preparedness

- Kennedy Assassination Newspaper Value A Comprehensive Guide To Collectible History

History and Evolution of Heat Press Technology

The history of heat press technology dates back to the 1960s when the first heat press machines were introduced. Initially, these machines were large and cumbersome, making them impractical for small businesses. Over the years, advancements in technology have led to the development of compact and efficient heat press machines that are now widely used in the printing industry.

Today, transfer express heat press machines are equipped with digital controls and advanced features that enhance their performance and usability. These innovations have made it easier for businesses to produce high-quality prints with minimal effort.

Types of Transfer Express Heat Press Machines

There are several types of transfer express heat press machines available in the market, each designed for specific applications. Below is a list of the most common types:

- Clamshell Heat Press: The upper platen opens like a clamshell, providing easy access to the material.

- Swing-Away Heat Press: The upper platen swings away from the lower platen, allowing for easy placement and removal of materials.

- Draw Heat Press: The lower platen slides out like a drawer, making it easier to position the material.

- Multi-Station Heat Press: These machines have multiple stations, allowing for simultaneous printing of multiple items.

Choosing the Right Machine for Your Business

Selecting the right transfer express heat press machine depends on several factors, including the size of your business, the type of materials you work with, and your budget. It's important to consider these factors carefully to ensure you choose a machine that meets your specific needs.

Applications of Transfer Express Heat Press

Transfer express heat press technology has a wide range of applications across various industries. Some of the most common applications include:

- Custom apparel printing

- Sublimation printing on ceramics and metal

- Decorating promotional products

- Creating personalized gifts and souvenirs

As the demand for customized products continues to rise, businesses are finding new and innovative ways to use transfer express heat press technology.

Benefits of Using Transfer Express Heat Press

There are numerous benefits to using transfer express heat press technology in your business. Some of the key advantages include:

- High-Quality Prints: Transfer express heat press produces vibrant and durable prints that withstand washing and wear.

- Versatility: The technology can be used on a variety of materials, allowing for diverse product offerings.

- Cost-Effective: Once the initial investment is made, the cost per print is relatively low, making it an economical choice for businesses.

- Efficiency: The process is quick and easy, enabling businesses to produce high volumes of prints in a short amount of time.

Long-Tail Keywords and Variations

In addition to the main keyword "transfer express heat press," it's important to incorporate long-tail keywords and variations throughout the content. Examples include "custom heat press printing," "heat press machine for t-shirts," and "sublimation heat press."

Tips for Maximizing Efficiency

To get the most out of your transfer express heat press machine, consider the following tips:

- Calibrate your machine regularly to ensure accurate temperature and pressure settings.

- Use high-quality transfer paper and inks to achieve the best results.

- Experiment with different materials to expand your product range.

- Invest in training for your staff to ensure they are proficient in operating the machine.

Best Practices for Quality Control

Implementing quality control measures is essential to maintaining consistent results. Regularly inspect your prints for defects and adjust your machine settings as needed. Keeping detailed records of your production process can also help identify areas for improvement.

Maintenance and Troubleshooting

Proper maintenance is crucial for the longevity and performance of your transfer express heat press machine. Follow these maintenance tips:

- Clean the machine regularly to prevent buildup of residue and debris.

- Inspect the heating element and pressure plate for signs of wear and tear.

- Follow the manufacturer's guidelines for lubrication and other maintenance tasks.

If you encounter any issues with your machine, refer to the troubleshooting guide provided by the manufacturer. Common problems include uneven heating and pressure, which can usually be resolved by adjusting the machine settings.

Comparison with Other Printing Methods

While transfer express heat press technology offers many advantages, it's important to compare it with other printing methods to determine the best option for your business. Below is a comparison of transfer express heat press with screen printing and digital printing:

Transfer Express Heat Press vs. Screen Printing

Transfer express heat press is generally more cost-effective for small to medium-sized orders, while screen printing is better suited for large-scale production. However, heat press technology offers greater flexibility in terms of design and material options.

Transfer Express Heat Press vs. Digital Printing

Both methods produce high-quality prints, but transfer express heat press is often preferred for its durability and versatility. Digital printing, on the other hand, is ideal for complex designs and photo-realistic images.

Market Trends and Future Prospects

The market for transfer express heat press technology is expected to grow significantly in the coming years. Factors driving this growth include increasing demand for personalized products, advancements in technology, and the rise of e-commerce.

As businesses continue to adopt transfer express heat press technology, we can expect to see further innovations in machine design and functionality. This will enable even greater efficiency and productivity in the printing industry.

Conclusion

In conclusion, transfer express heat press technology is a powerful tool for businesses looking to enhance their printing capabilities. By understanding the basics, exploring the various applications, and implementing best practices, you can achieve outstanding results and grow your business.

We invite you to share your thoughts and experiences with transfer express heat press technology in the comments section below. Don't forget to explore our other articles for more valuable insights and tips on growing your business. Thank you for reading!

- Iowa Dot Road Conditions A Comprehensive Guide For Safe Travel

- Comprehensive Guide To Msg Seating Chart For Concerts

Heat Press Transformation Shop Visit Transfer Express Blog

Heat Press Craft Express Official

Heat Press Craft Express Official